Old oil and oily waste must be treated and/or recycled as hazardous waste. Send us an enquiry

Search

Company locations

The whole picture – with just a single click. Find out here where our branches are located, what services they offer and how to contact them.

REMONDIS Group locations

Discover the world of REMONDIS with its 1,000+ branches and associated companies in more than 30 countries across Europe, Africa, Asia and Australia.

Thermal treatment of waste – a part of the circular economy

The incineration of hazardous waste – i.e. the thermal treatment and disposal of residual materials and contaminants that cannot be recycled for reuse – is one of REMONDIS Industrie Service’s core areas of expertise. We have an excellent network of high-performance waste incineration plants able to dispose of such hazardous substances. For example our hazardous waste incineration plants in Bramsche, Brunsbüttel and Wesseling. What’s more, we also own shares in a wide variety of waste incineration plants across the whole of Germany. Thanks to this network of facilities, we are not only able to treat and dispose of practically all types of solid, liquid and gaseous waste, such as distillation residue, acids and hydrofluorocarbons. It also means that we have short transport routes and can respond quickly to our customers’ needs.

Hazardous waste treatment with REMONDIS Industrie Service

Wide range of substances

We are able to accept all types of hazardous waste in all types of storage containers (for example IBCs, drums and AS containers).

In-house analytics

All incoming waste is analysed in our own laboratory and the results used to assign the materials to different quality categories.

Diverse feed mechanisms

We have both direct injection systems for reactive liquids as well as separate feed mechanisms for PCB-contaminated oil. Repacking areas, drum elevators and scrap shears are also available.

A comprehensive range of services

Our portfolio covers everything needed to make the disposal of your dangerous substances as easy as possible for you – from advice, to transport, through to drawing up waste manifests and other documentation.

Creation of synergies

Thanks to our wide range of treatment processes, we are able to make the very most of the materials, even hazardous waste.

Hazardous waste: a source of raw materials and energy

We specialise in making hazardous waste safe. And we do this by operating certified facilities with state-of-the-art technologies across Germany and Europe. Collaborating with partners from the worlds of research and business, we are continuously working on finding new recycling processes and expanding our portfolio of services. We make the very most of the recycling potential of these materials whenever we can to promote and advance a future-oriented circular economy. Wherever possible, we recover recyclable materials so they can be used to make new products or transformed into refuse-derived fuel. Besides operating a large network of specialist treatment facilities and chemical-physical plants, REMONDIS Industrie Service also has reliable capacities for incinerating hazardous, non-recyclable wastes. Here, too, priority is put on conserving natural resources, substituting fossil fuels and generating energy – ensuring that our hazardous waste incineration plants help promote the sustainable development of our society and are part of climate action programmes.

Definition of a hazardous waste incineration plant as per the BImSchV

A definition of hazardous waste incineration plants can be found in the 14th BImSchV [Federal Immission Control Act]. Referring to hazardous waste, this act talks of “facilities for disposing of or recycling solid, liquid or gaseous (stored in containers) waste, landfill gas or other gaseous substances with combustible contents using thermal processes, in particular degassing, plasma processes, pyrolysis, gasification, incineration or a combination of these processes”.

Safely treating hazardous waste

No matter whether it be in the chemicals industry or automotive sector, in a lab or a commercial firm: everyone producing hazardous waste wishes these substances to be disposed of in a comprehensive, uncomplicated and safe way. And this is precisely what our hazardous waste thermal treatment division delivers. When you work with us, you not only benefit from the fact that we can provide the whole range of services needed but also from our extensive capacities that can accept countless tonnes of dangerous substances. For example, liquid waste (such as solvents), infectious substances and organic compounds to name just a few.

“We can thermally treat very different types and volumes of organic and inorganic residual materials in our hazardous waste incineration plants.”

Stefan, Approvals & Safety

So how exactly is hazardous waste incinerated?

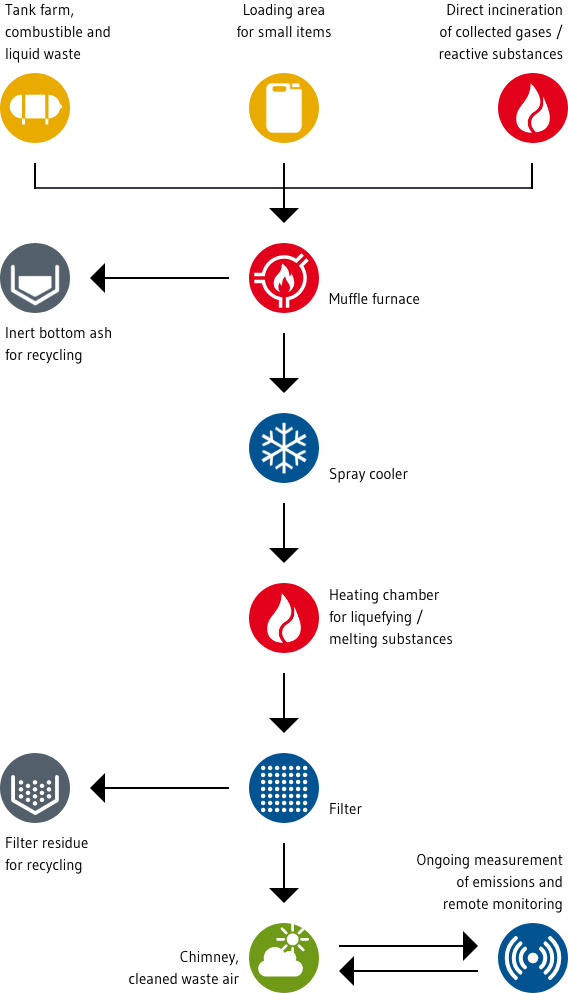

Liquid, pumpable and gaseous wastes and small volumes of solid waste such as carbides, phosphides and other reactive chemicals are incinerated in the high temperature incinerator in Bramsche at particularly high temperatures (over 1,100°C). As is the case with all our facilities, our operations here are targeted at protecting the environment and conserving natural resources. This means that the whole incineration process is not only very clean – it adheres strictly to all emission ceiling values – but also extremely effective. Even here, at the lowest level of the waste hierarchy, it remains our mission to make the very most of the materials and thermal recycling potential of the substances being treated. This includes, for example, processing particularly high calorific waste containing few emission-relevant substances separately so that it can be used to produce refuse-derived fuel. What’s more, the emptied storage containers are cleaned in our own washing facility and then sent on for reuse.

How waste is treated at the high temperature incinerator in Bramsche

The thermal treatment of waste means: protecting people and the environment, conserving natural resources

There is a good reason why people working in the circular economy talk of thermal treatment rather than waste incineration or even hazardous waste incineration. While it may be true that many types of hazardous waste can’t be recycled for reuse, it certainly doesn’t mean that they are of no value. As is always the case when treating waste, we run our incineration facilities with sustainability in mind. And so recovering energy from residual materials helps to reduce consumption of fossil fuels, such as coal, oil and gas. What’s more, the REMONDIS Group transforms the FGD gypsum from our flue gas desulphurisation systems into high quality building materials – a further way to help conserve natural resources.